What is ultrasound?

Sound is a longitudinal wave. This means it vibrates in the same direction that it transfers its energy.

The frequency of a sound, measured in Hertz (Hz), tells us its pitch. Sounds with high frequencies are high-pitched 'squeaky' sounds, while sounds with low frequencies are the low-pitched 'deep' sounds.

Ultrasound is classed as any sound wave with a frequency greater than 20,000 Hz. These frequencies are so high that humans are unable to hear them.

Uses of ultrasound in hospitals

You are probably familiar with ultrasound scans, which are used to look inside the body, and are most commonly used for looking at babies growing inside their mother. However, ultrasound has many uses other than medical applications, and we will explore them here.

Non-medical uses of ultrasound

One use of ultrasound is cleaning jewellery.

The tiny grooves inside something like a ring are too difficult to clean thoroughly with a cloth or a wipe. The jewellery is placed in a mixture of water and a cleaning product. Ultrasound waves are then applied to the jewellery, creating little bubbles that attach to dirt particles and shake it off the surface. Ultrasound can also break down and kill bacteria, to sterilise surfaces.

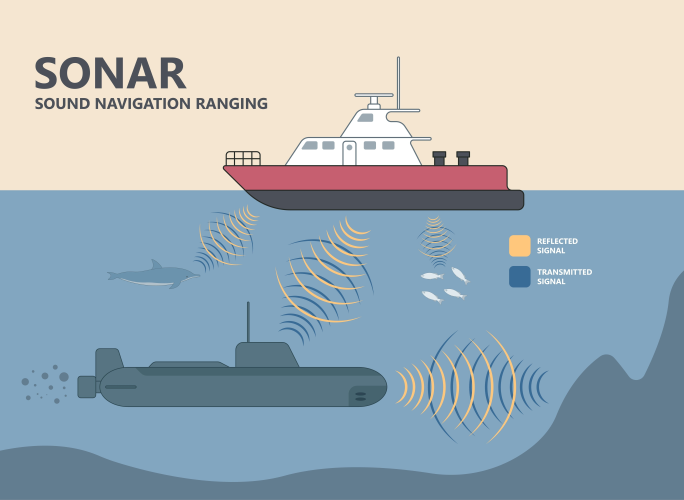

SONAR is another use of ultrasound. It is used in boats and submarines.

SONAR stands for SOund Navigation And Ranging. It is a navigation system that consists of sending out an ultrasound pulse and timing how long it takes to reflect off a surface. The time taken to reflect back allows the boat or submarine to calculate how far away an object is. So, by measuring their own 'echoes', this can be used to work out the depth of the water, or detect obstacles.

Bats, whales, and dolphins are animals that use their own version of sonar to navigate. (This is called echolocation). These animals 'squeak' in ultrasound and wait to hear the sound of their own echo, allowing them to detect objects or prey.

Finally, ultrasound is used in manufacturing and engineering for quality checks.

For example, if an engineer wants to check the quality of a pipe underground, they can send a pulse of ultrasound into the ground and wait to detect the sound reflected back to the surface. This process allows the engineer to find any faults, such as cracks in the pipe. The advantages of this method of checking the quality of the material is that the pipes can be checked without needing to dig into the ground, and it does not cause any damage to the pipes.

Right, let's have a go at some questions now.